Packaging Act

New legal framework since January 1, 2019

As registered auditors, we carry out the legally required audits in accordance with Section 11 VerpackG and advise you on all related issues.

The Packaging Act has replaced the previous Packaging Ordinance. With this law, the Central Packaging Register (ZSVR) has been established. In addition to the premature registration of producers, its task is to receive and verify the plausibility of data reports (manufacturers and systems) as well as declarations of completeness and proof of volume flow. It is also responsible for calculating the market shares of the dual systems.

In addition to the national producer register, the Central Agency also maintains a register of auditors, which is divided into two sections. A distinction is made between registered experts and registered professionals (auditors, tax consultants and sworn accountants). The ZSVR also draws up the “Audit Guidelines for Declarations of Completeness” to be used by the auditors in agreement with the Federal Cartel Office for the respective reference year.

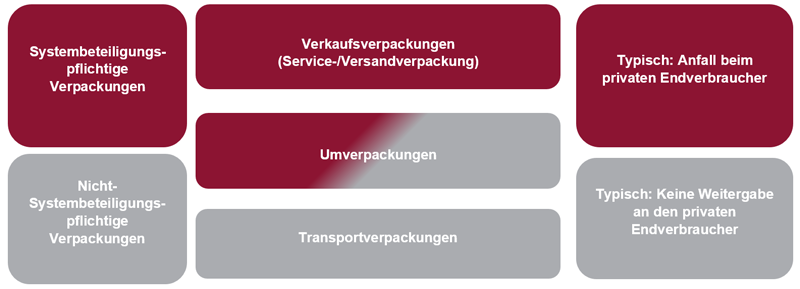

Figure 1: Packaging boundaries

Scope of application and definitions according to the Packaging Act

The Packaging Act applies to “manufacturers”. According to the law, a manufacturer is anyone who places packaging on the market or imports packaging for the first time and on a commercial basis. Under the Packaging Act, “packaging” equals sales packaging (sales unit consisting of goods and packaging) that is typically offered to the final consumer.

When deciding whether packaging is subject to system participation or not, the criterion of the typical source of waste generation is used. If the packaging typically leads to waste disposal from a private final consumer after the use of the goods, it is said to be subject to system participation. Packaging is divided into sales packaging, secondary packaging and transportation packaging according to its use:

- Sales packaging is defined as service and transportation packaging that is only filled at the final distributor and is intended to enable handover or shipment to the final consumer. Typical source of waste generation: Private final consumer; therefore subject to system participation

- Secondary packaging is generally used to bundle a certain number of sales units and offer them to the final consumer or to stock the sales shelf. Typical source of waste generation: Not exclusively private final consumer; partly subject to system participation

- The sole purpose of transportation packaging is to enable and facilitate the handling and transportation of goods. It is typically not passed on to the final consumer. Consequently, there is no obligation to participate in the system.

The declaration of completeness according to the VerpackG

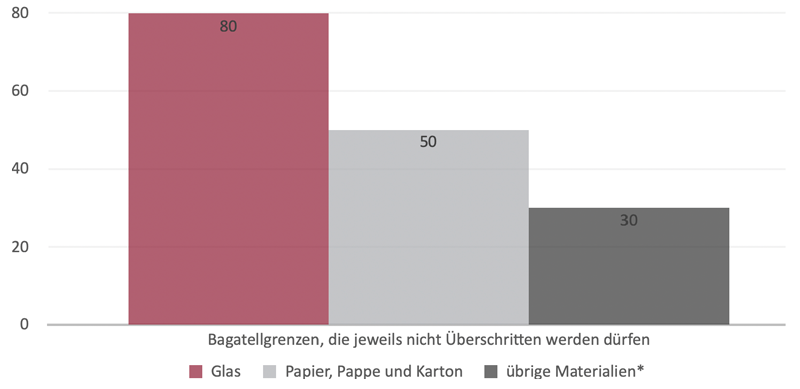

All manufacturers who place packaging on the market and exceed the de minimis limits are obliged to submit a declaration of completeness.

A distinction is made between glass (80 tons), paper and cardboard (50 tons) and other materials (30 tons) that are placed on the market by the manufacturer. If one of the three limits mentioned is exceeded, the declaration of completeness must be submitted by May 15th of the following year without being requested to do so. Below these de minimis limits, an official request for mandatory submission is required.

Regardless of any packaging quantities, manufacturers are obliged to participate in a (dual) system already from the very first kilogram placed on the market as well as to register as a manufacturer with the “Stiftung Zentrale Stelle Verpackungsregister” (Central Packaging Register Foundation) in advance.

Minority limits in tonnes (to)

*other materials include plastics, composites, ferrous metals and aluminium

Figure 2: Minority limits after packagingG

The audit of the declaration of completeness

Subject of the audit is the information from the declaration of completeness. The audit is based on the audit guidelines of the ZSVR and on IDW PS 332 when using experts for the measurement and weighing of packaging or for the preparation of technical reports. In-house and third-party weighing must be carried out in accordance with the MessEG and MessEV.

The ZSVR’s “Catalog of Packaging Subject to System Participation” and its decision on applications pursuant to section 26 (1) sentence 2 no. 23- 26 VerpackG are authoritative for the classification of individual packaging from the point of view of the system participation requirement.

The inspection guidelines issued by the ZSVR specify the ten inspection fields shown below:

- Register data comparison: checking the data stored in the register (manufacturer data, brands and data reports), the data reports to the (dual) system and the manufacturer’s data status for consistency.

- Checking the system participation contracts: Verification of system participation contracts with regard to timely conclusion and their legally compliant content using the registration number recorded in the LUCID producer register.

- Structural and functional audit of the internal control system: The audit relates to the controls implemented by the manufacturer to ensure that the information in the declaration of completeness is free of errors.

- Delimitation of packaging/non-packaging (and corresponding system participation): Verification of the complete recording and correct delimitation, also with regard to their obligation to participate in the system, of the types of packaging in accordance with the ZSVR.

- Master data maintenance in the company: Comparison of the master data recorded in the company from the point of view of completeness and correct allocation of the system participation obligation with regard to its determination, recording and up-to-dateness.

- Sample examination: Individual case examinations for a sample selection that prove the correct application of the last two points, the delimitation of packaging/non-packaging and master data maintenance.

- Trial run quantity determination: Simulation of a quantity determination (annual/monthly) at the manufacturer’s premises in order to be able to verify the reliable reproducibility of the results of a quantity determination.

- Reconciliation of financial accounting: An on-site audit that serves to determine the complete settlement of the determined packaging quantities subject to system participation with a (dual) system.

- Final verification of quantities subject to system participation: Final check as to whether the quantities determined in the course of the audit correspond to the actual quantities subject to system participation, taking into account authorized deductions in accordance with the law.

- Industry solutions: If industry solutions exist outside the dual system in which the manufacturer participates, audit procedures regarding the eligibility of the packaging to participate must be checked.